Oli ke e 'ngoe ea lisebelisoa tsa bohlokoa bakeng sa nts'etsopele ea mahlale le thekenoloji naheng ea China, 'me boemo ba ho hlaphoheloa ha oli le bona bo fetohile bothata ba indasteri ea China.Maemo a metsi a petroliamo naheng ea rona esale a le holimo.Mokhoa oa ho fokotsa metsi le oona o fetohile bothata bo boholo indastering.Theknoloji e phahameng ea ho khutlisa oliho sebelisa polymer joalo ka sejari ke mokhoa o sebetsang oa ho rarolla bothata bona.Mokhoa ona o ntlafatsa ka katleho ho hanyetsa letsoai la oli le ho fokotsa tšilafalo ea tikoloho.Ka hona, nts'etsopele e ncha ea li-polymer tse ncha ke senotlolo sa ho khothaletsa theknoloji ea China ea ho hlahloba oli.

Mantsoe a sehlooho:polymer, theknoloji e phahameng ea ho khutlisa oli, ts'ebetso ea nts'etsopele, tataiso ea mantlha ea lipatlisiso

Hona joale, oli ea Chaena e na le metsi a mangata, 'me ho itšetleha ha eona ho oli ea linaheng tse ling ho ntse ho eketseha.Oli e nka boemo bo bongata Chaena.Ka hona, re tlameha ho netefatsa hore oli e ka eketsa tlhahiso motheong oa tlhahiso e tsitsitseng le tšebeliso e sireletsehileng.Ke bothata ba bohlokoa ka ho fetisisa ho fokotsa metsi a oli ka katleho, 'me ho hlaphoheloa ha oli ea thuto e phahameng ka ho sebelisa polymer joalo ka sejari ke e' ngoe ea mehato e sebetsang ka ho fetisisa ea ho rarolla bothata bona.Ts'ebetsong ena, polymer e ka sehloohong kepolyacrylamide, e ka bakang ho se tsitse, tšilafalo ea tikoloho, ho hanyetsa letsoai le lintlha tse ling, kahoo lintlha tsena li bakile mathata a theknoloji a lokelang ho rarolloa tseleng ea papatso.Bakeng sa ho khothaletsa nts'etsopele ea indasteri ea oli, lipatlisiso tsa li-polymers tse ncha li fetohile theknoloji ea bohlokoa.

1. Ts'ebetso ea nts'etsopele ea mahlale a phahameng a ho khutlisa oli

Theknoloji ea thuto e phahameng ea ho khutlisa oli e bile le liphetoho tse tharo tse kholo tsa nts'etsopele.Tsoelo-pele ea pele e ne e le ho tloha ka 1950 ho ea ho 1969. Oli e boima e ne e sebelisoa haholo indastering ea peterole ho finyella theknoloji ea ho tlosa oli ea mouoane, kahoo oli e boima e ne e sebelisoa haholo lefatšeng.Khatelo-pele ea bobeli e ne e le ho tloha ka 1971 ho ea ho 1980. Ka nako eo, likhohola tsa mouoane e ne e le eona tsela e ka sehloohong, empa ho tsosolosoa ha oli e phahameng ka likhohola tsa lik'hemik'hale ho ile ha ntlafatsoa ka potlako.Leha ho le joalo, nts'etsopele ea likhohola tsa lik'hemik'hale ka nako eo e ne e thibetsoe ke lintlha tse ngata tse sa tsitsang, tse kang litšenyehelo tse phahameng, tšilafalo e boima, joalo-joalo. Nts'etsopele ea boraro e qalile ka 1990, 'me theknoloji ea ente ea khase e sa tšoaneng e ntlafalitse haholo Chaena.Theknoloji ena e na le melemo ea litšenyehelo tse tlaase tsa tšebeliso, mefuta e mengata ea kopo, 'me e ka finyella litlhoko tsa ts'ireletso ea tikoloho.

2, theknoloji e ncha ea ho khutlisa oli ea polymer tertiary

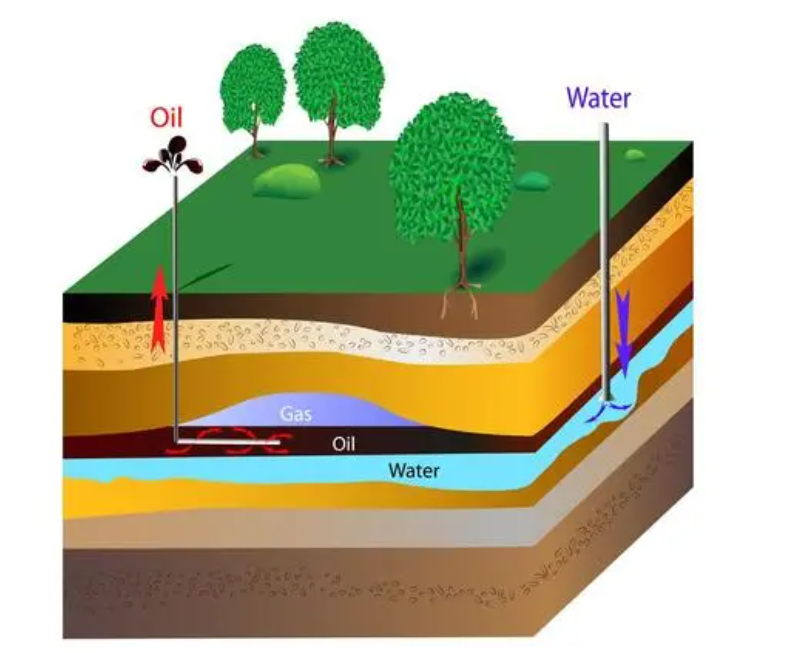

Theknoloji ena e bokella mokelikeli oa oli ka makhetlo a mararo.Ho tsosolosoa ha oli ea mantlha ho bolela matla a polokelo nakong ea ts'ebetso ea oli;Mokhoa oa ho khutlisa oli ea bobeli ke ho tlatsa letamo ka matla a phallang, hangata ho tlatsetsa khase le metsi letamong;Phetoho ea oli ea maemo a holimo e sebelisa lik'hemik'hale ho fetola ts'ebetso e kopaneng ea khase, metsi, oli le majoe.Har'a mahlale a mararo a ho khutlisa oli, theknoloji ea boraro ea ho khutlisa oli ke eona e tsebahalang le e sebelisoang haholo kajeno.Theknoloji ena e na le ho hlaphoheloa hantle ho feta tse ling tse peli, e ka fokotsa ka katleho ho khaoha ha metsi sebakeng sa oli, 'me ke mohato o ka sehloohong oa ho ntlafatsa boleng ba oli Chaena.Li-polymer tse ncha li teng ka har'a sebopeho sa limolek'hule, tse ka ntlafatsang ho hanyetsa letsoai la limolek'hule tsa polymer le ho ntlafatsa haholo pholiso ea oli.Polymer ena e ncha e sebelisitsoe haholo libakeng tse kholo tsa oli Chaena, 'me phello e bohlokoa haholo, e bonahetseng ka ts'ebetso.Ha ho bapisoa lepolyacrylamide e tloaelehileng, molek'hule ena e ncha ea polymer ha e fokotse haholo litšenyehelo tsa tšebeliso, empa hape e ka sireletsa tikoloho le ho eketsa sekhahla sa ho hlaphoheloa ha oli ka liperesente tse peli, ho ntlafatsa haholo sekhahla sa ho khutlisa oli.

3. Litaelo tse ka sehloohong tsa lipatlisiso tsa ho hlaphoheloa ha oli ea thuto e phahameng

Taba ea pele, lebaleng la kajeno la oli, surfactant e nang le phello e ntle ea ho falla ha oli le litšenyehelo tse tlase ke tataiso ea lipatlisiso sethaleng sena sa nts'etsopele ea theknoloji ea ternary composite system displacement.Ho feta moo, khetho ea surfactant e ithutoa e le ho fokotsa ka katleho litšenyehelo tsa surfactant tsamaisong ea ternary coincidence.Hajoale, sepheo sa lipatlisiso sa indasteri ea peterole ke ho fokotsa phello ea karohano ea chromatographic, 'me litharollo tse ka khonehang le tse sebetsang li hlahisitsoe libakeng tse fapaneng tse amanang le oli, tse fanang ka motheo o tiileng bakeng sa foromo e kholo ea sebaka se tšoanang.

Ea bobeli, ho ntlafatsa ho hlaphoheloa ha oli, likhohola tse entsoeng ka foam le tsona ke theknoloji e sebetsang hantle.Theknoloji ena ha e kopanye feela melemo ea ho hlaphoheloa ha oli e chesang, empa e boetse e na le melemo ea ho falla ha oli ea foam, hape e na le phello ea ho falla ha oli ea naetrojene le carbon dioxide, e ntlafatsa haholo phello ea ho falla ha oli.

Theknoloji ena e ka khona ho kenella ka har'a likheo tse nyane le masoba a ke keng a fihleloa ke sistimi ea ternary composite ho tlosa matheba a setseng a oli.Liteko tse amehang li bonts'a hore ntlha ea ho khutlisa oli e ntlafatsoa ka katleho ke likhohola tsa foam.Ka mor'a ente ea polymer, ka mocheso o ntseng o eketseha, likhohola tse entsoeng ka foam le tsona li ntlafatsa ho hlaphoheloa ha oli.Tlas'a maemo a phahameng a mocheso, ho hlaphoheloa ha oli ho ka fihla ho 16%.

Ntlha ea boraro, lilemong tsa morao tjena, ho falla ha oli ea likokoana-hloko ho tsoetse pele ka potlako ho theknoloji e phahameng ea ho khutlisa oli, 'me hoo e ka bang libaka tsohle tse kholo tsa oli li entse lipatlisiso tse nepahetseng mabapi le ho falla ha oli ea likokoana-hloko le ho hlaphoheloa ha oli.Ho na le libaka tse fetang 20 tsa tlhahlobo ea oli ea microbial naheng ea China.Leha ho le joalo, theknoloji ea hajoale ha e ea phethahala, 'me mathata a mang a tekheniki a ntse a hloka ho rarolloa, joalo ka lipatlisiso mabapi le ho hlahloba likolone tsa likokoana-hloko tikolohong ea tlhaho.

4. Mathata

Tšebeliso ea li-polymer masimong a oli e ka ntlafatsa haholo sekhahla sa ho khutlisa oli mme ka hona ho tlisa phaello e kholo ea moruo, empa ha ho letho lefatšeng le phethahetseng.Tse latelang ke mathata a mang ts'ebelisong e sebetsang ea li-polymers:

(1) Ho koaloa ha Wellhead

Ntho ea bohlokoa ea ho netefatsa hore oli e hlaphoheloa ke polymer, e ka fokotsang haholo metsi a oli.Ka lebaka la tšitiso ea lintlha tse fapaneng, ha khatello ea ente ea li-polymer tse ling e phahama 'me e atamela khatello ea fracture, litekanyetso tsa bona tsa khatello ha li finyelle litlhoko,' me ha molumo oa ente o fokotsehile, ho hlajoa ha polymer plugging ho hlaha selibeng, e amang katleho ea tlhahiso ea oli.

(2) Kabo ea ente ka likhoerekhoere

Sepheo ke ho fokotsa litšenyehelo tsa tšebeliso ea likhohola tsa polymer le ho fokotsa tšebeliso ea metsi a hloekileng bakeng sa likhohola tsa polymer.Ho fihlela joale, tsoelo-pele ea pele e entsoe lipatlisisong tsa ente ea polymer ka likhoerekhoere tse mafura.Mokhoa oa pele ke ho sebelisa likhoerekhoere tse mafura ka kotloloho ho hlapolla polymer e hananang le letsoai.Pele ho hlapolloa, litšila tsa baktheria li tlameha ho tlosoa ho netefatsa hore viscosity ea polymer e ke ke ea fetoloa.Mokhoa oa bobeli ke oa ho hloekisa likhoerekhoere tse mafura esale pele ho etsa hore boleng ba metsi a eona bo fihle ho metsi a hloekileng a letsoai, ebe o a kenya ka har'a polymer.Leha ho le joalo, lipatlisiso tsa morao-rao ha li na kutloisiso e tebileng ea mochine oa viscosity o amang polymer, 'me mokhoa oa ho lokisa polymer ka likhoerekhoere tsa likhoerekhoere o hloka ho ntlafatsoa le ho ntlafatsoa.

5, Qetello

Theknoloji ea lipatlisiso tsa thuto e phahameng e kopanya theknoloji e phahameng le e ncha ea fisiks, k'hemistri le biology ho tsoela pele ho ntlafatsa theknoloji ea ho hlahloba oli.Sebakeng sa indasteri ea peterole,thekenoloji ea ts'ebeliso ea maemo a holimoe thehiloeng ho polymer e fihletse ts'ebeliso ea indasteri le e kholo, e ka fanang ka mekhoa e matla ea tekheniki bakeng sa ts'ebeliso ea peterole ea China.Leha ho le joalo, ka ho matlafatsoa ha mekhoa ea botekgeniki, mathata a mang a tlang a re hlorisa hlooho.Mathata a mabeli a boletsoeng sehloohong sena ke a mang a mangata a ’ona.Ka hona, tseleng ea makhetlo a mararo a lipatlisiso le nts'etsopele ea merafo, re ke ke ra phutholoha ka nako leha e le efe.Re lokela ho matlafatsa boikitlaetso ba lipatlisiso tsa mahlale ho sebetsana le mathata a bohlokoa, le ho rarolla mathata a thekenoloji ea merafo hamolemo le ka katleho.

Nako ea poso: Oct-19-2022